5154 Series Stationary Drum Rollers

Rotating drums to mix or blend material inside a closed drum saves time, labor and money. Rotate a drum to mix the contents, and ensure homogeneity with fewer hazards. Remix settled or stratified ingredients. Raise and redistribute solids that have settled during shipping and storage.

Key features

- Roll standard 55-gallon (210 liter) steel drum to mix contents

- 1-5154 Series Single Drum Rollers roll ONE drum

- 2-5154 Series Double Drum Rollers roll 1 or 2 drums at a time

- Roll Drums with 6" to 28" (15 to 71 cm) diameter, up to 40" (102 cm) tall

- Models available with fixed or variable drum rotating speeds

- Load horizontal drum with your hoist.

- Maximum ambient operating temperature: 140° F (60° C)

- To roll plastic drum, order with POLY Option

- To roll 1-to-5 gallon can, install Idler Attachment

Roll closed drum to gently mix contents. Remix valuable settled or stratified ingredients, or smooth rough parts by tumbling with media.

Mixing in a closed drum eliminates the hazards of worker exposure, and the messy cleanup associated with insertion mixers.

Mixing times vary depending on factors such as…

Mixing in a closed drum eliminates the hazards of worker exposure, and the messy cleanup associated with insertion mixers.

Mixing times vary depending on factors such as…

- Drum RPM

- Drum size

- Fullness of drum (clearance space within drum)

- Liquid vs powder or granulated drum contents

- Degree of uniformity / homogeneity required

- Ambient temperature

Load Horizontal Drum with Your Hoist

Model Chart

What features do you need?

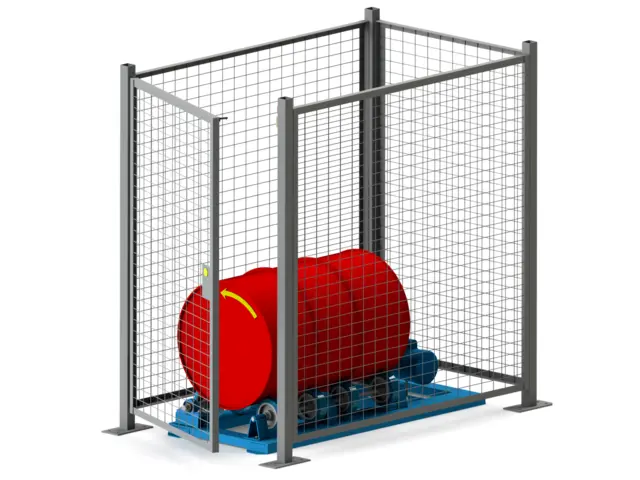

| Motor style | Phase | Voltage / Amp Draw | Explosion proof | Drum RPM | Control Package | Guard Enclosure Kit | Model |

|---|---|---|---|---|---|---|---|

| 60Hz | 1 | 115v / 7.4 208v / 4.3 230v / 3.7 |

N | 20 RPM |

5998-P 5999-P |

gek-1-5154-1 |

1-5154-1 |

| 60Hz | 3 | 115v / 1.6 230v / 1.6 460v / 0.8 |

N | 20 RPM Add Morse Control Package for 1 to 30 RPM Variable Speed |

CP-1-5154-1-115 CP-1-5154-1-230 CP-1-5154-3-230 CP-1-5154-3-460 |

GEK-1-5154-3 |

1-5154-3 |

| - | N | 20 RPM Vary RPM with air flow and pressure |

GEK-1-5154-A |

1-5154-A | |||

| 60Hz | 1 | 115v / 7.4 208v / 3.9 230v / 3.7 |

Y | 20 RPM |

CP-1-5154-E1-115 CP-1-5154-E1-208 CP-1-5154-E1-230 |

GEK-1-5154-E1 |

1-5154-E1 |

| 50Hz | 1 | 220v / 3.6 | Y | 16 RPM |

CP-1-5154-E1-220-50 |

GEK-1-5154-E1 |

1-5154-E1-50 |

| 60Hz | 3 | 208v / 2.1 230v / 2.0 460v / 1.0 |

Y | 20 RPM |

CP-1-5154-E3-208 CP-1-5154-E3-230 CP-1-5154-E3-460 |

GEK-1-5154-E3 |

1-5154-E3 |

| 50Hz | 3 | 230v / 1.7 400v / 1.0 |

Y | 16 RPM |

CP-1-5154-E3-230-50 CP-1-5154-E3-400-50 |

GEK-1-5154-E3 |

1-5154-E3-50 |

| 60Hz | 3 | 575v / 0.7 | Y | 20 RPM |

CP-1-5154-E3-575 |

GEK-1-5154-E3 |

1-5154-e3-575 |

| 60Hz | 1 | 115v / 7.4 230v / 3.7 |

N | 20 RPM |

5998SS-P 5999SS-P |

gek-1-5154-1 |

1-5154SS-1 |

| 60Hz | 3 | 230v / 1.6 460v / 0.8 |

N | 20 RPM Add Morse Control Package for 1 to 30 RPM Variable Speed |

CP-1-5154SS-1-115 CP-1-5154SS-1-230 CP-1-5154SS-3-230 CP-1-5154SS-3-460 |

GEK-1-5154-3 |

1-5154SS-3 |

| - | N | 20 RPM Vary RPM with air flow and pressure |

GEK-1-5154-A |

1-5154SS-A | |||

| 60Hz | 1 | 115v / 7.4 208v / 3.9 230v / 3.7 |

Y | 20 RPM |

CP-1-5154SS-E1-115 CP-1-5154SS-E1-208 CP-1-5154SS-E1-230 |

GEK-1-5154-E1 |

1-5154SS-E1 |

| 50Hz | 1 | 220v / 3.6 | Y | 16 RPM |

CP-1-5154SS-E1-220-50 |

GEK-1-5154-E1 |

1-5154SS-E1-50 |

| 60Hz | 3 | 208v / 2.1 230v / 2.0 460v / 1.0 |

Y | 20 RPM |

CP-1-5154SS-E3-208 CP-1-5154SS-E3-230 CP-1-5154SS-E3-460 |

GEK-1-5154-E3 |

1-5154SS-E3 |

| 50Hz | 3 | 230v / 1.7 400v / 1.0 |

Y | 16 RPM |

CP-1-5154SS-E3-230-50 CP-1-5154SS-E3-400-50 |

GEK-1-5154-E3 |

1-5154SS-E3-50 |

| 60Hz | 3 | 575v / 0.7 | Y | 20 RPM |

CP-1-5154SS-E3-575 |

GEK-1-5154-E3 |

1-5154SS-E3-575 |

| 60Hz | 1 | 115v / 12.8 208v / 7.0 230v / 6.0 |

N | 20 RPM |

5996-P 5997-P |

GEK-2-5154-1 |

2-5154-1 |

| 60Hz | 3 | 115v / 2.8 230v / 2.8 460v / 1.4 |

N | 20 RPM Add Morse Control Package for 1 to 30 RPM Variable Speed |

CP-2-5154-1-115 CP-2-5154-1-230 CP-2-5154-3-230 CP-2-5154-3-460 |

GEK-2-5154-3 |

2-5154-3 |

| - | N | 20 RPM Vary RPM with air flow and pressure |

GEK-2-5154-A |

2-5154-A | |||

| 60Hz | 1 | 115v / 12.4 230v / 6.2 |

Y | 20 RPM |

CP-2-5154-E1-115 CP-2-5154-E1-230 |

GEK-2-5154-E1 |

2-5154-e1 |

| 50Hz | 1 | 220v / 6.2 | Y | 16 RPM |

CP-2-5154-E1-220-50 |

GEK-2-5154-E1 |

2-5154-E1-50 |

| 60Hz | 3 | 208v / 3.1 230v / 3.0 460v / 1.5 |

Y | 20 RPM |

CP-2-5154-E3-208 CP-2-5154-E3-230 CP-2-5154-E3-460 |

GEK-2-5154-E3 |

2-5154-E3 |

| 50Hz | 3 | 230v / 3.5 400v / 2.0 |

Y | 16 RPM |

CP-2-5154-E3-230-50 CP-2-5154-E3-400-50 |

GEK-2-5154-E3 |

2-5154-E3-50 |

| 60Hz | 3 | 575v / 1.2 | Y | 20 RPM |

CP-2-5154-E3-575 |

GEK-2-5154-E3 |

2-5154-e3-575 |

California Proposition 65 Information

WARNING: This product can expose you to chemicals including barium sulfate, cobalt, titanium dioxide, and 2-methylimidazole, which are known to the State of California to cause cancer, and bisphenol-A, which is known to the State of California to cause birth defects or other reproductive harm.

For more information go to www.P65Warnings.ca.gov

For more information go to www.P65Warnings.ca.gov