Model 201VS-3-50

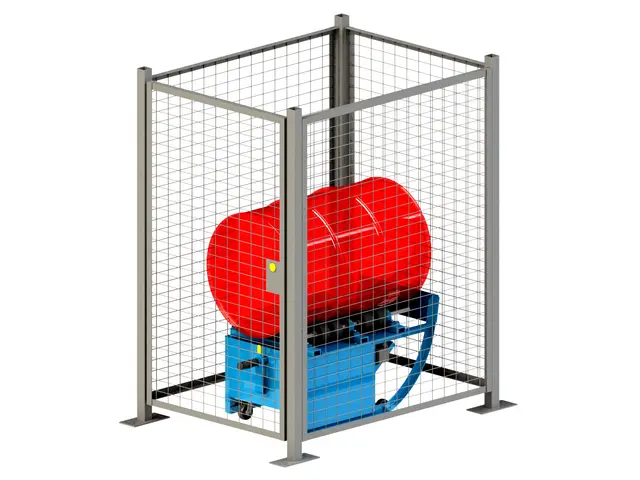

Portable Drum Roller, Variable Speed. 3-Phase 230/400V 50Hz Motor. REQUIRES Controls to Start/Stop. CE REQUIRES Enclosure with Interlock.

All about Model 201VS-3-50

- Model 201/20-3-50 has 1/2 HP 3-phase 230/400V 50Hz motor

- ONLY for country with 50Hz power supply

- Vary drum rolling speed from 13 to 20 drum RPM, based on 57 cm (22.5" cm) diameter

- Rolls drum on 8 wheels

-

Roll STEEL drum

- With 15 to 71 cm (6" to 28") diameter

- Up to 102 cm (40") tall

- To roll PLASTIC drum, add Option POLY-201 with extra wheels and end stop to prevent drum traveling length-ways

- To roll 2 to 20 Liter (1 to 5 gallon) size cylindrical can, add Idler Attachment 1-5P

- REQUIRES Electric Controls to Start / Stop Rotator

-

Electric Control Package sold separately

- Model CP-201-3-230-50 for 3-phase 230V 50Hz power supply

- Model CP-201-3-400-50 for 3-phase 400V 50Hz power supply

- Safety Enclosure with Interlock sold separately as Kit GEK-201-3

- IMPORTANT: OSHA, CSA and EU REQUIRE Safety Enclosure with Interlock

- Mix contents of a closed drum with a Compact, Portable Drum Roller

- Roll closed drum on its side to blend ingredients

- Tipping lever assists tilting drum onto roller. Engages drum 30" (76.2 cm) or taller.

- Maximum ambient operating temperature for Electric models: 140F (60C) and AIR models 195F (90.5C).

-

Factors to consider

- Ribs of rigid steel drum prevent traveling length-ways on roller

- Soft sided plastic drums require support of extra wheels and end stop to prevent drum travel

- Fiber drums require a belted drum roller with end stop

|

1-5P

Kit: Idler Attachment for CUSTOMER to install on 201 Series Drum Roller to roll 1 to 5 gallon size can |

|

2844Xi-P

Fully enclosed crate for export of 201 Series. Heat treated and certified IPPC compliant. |

|

4109Xi-P

Fully enclosed crate for export of 201 Series with Enclosure Kit (NOT set up). Crate is heat treated and certified IPPC compliant. |

|

CP-201-3-230-50

Control Package for 201 Portable Drum Roller. 3-Phase 230V 50Hz. Timer, Start/Stop, Emergency Stop, Loackable Fused Disconnect. |

|

CP-201-3-400-50

Control Package for 201 Portable Drum Roller. 3-Phase 400V 50Hz. Timer, Start/Stop, Emergency Stop, Lockable Fused Disconnect. |

|

CP-201S

SPL CONTROL PKG, 201 SERIES |

|

gek-201-3

Guard Enclosure Kit and Safety Interlock for customer to install with Morse 3-phase AC 201 Series Portable Drum Roller. |

|

POLY-201

OPTION: Factory Installed on NEW 201 Series to roll PLASTIC drum. Includes 4 Extra wheels, end stop to prevent drum travel, and chain to assist tipping. CANNOT be order without 201 Series drum roller. |

Optional Kit: Recommended Spare Parts for 201 and 201VS Series. (Click image for list of parts)

Example: 1120 is November 2020

Specifications

| Drum RPM | 13 to 20 RPM

RPM is based on 22.5" (57.15 cm) diameter drum. |

| Liquid capacity | 227.00 kg (500 Lb.) |

| Dryload capacity | 136.20 kg (300 Lb.)

A shifting dry load exerts greater stress on the drum rotator than the fluid motion of a liquid load. |

| Phase | 3 |

| Power | 0.37285 kw |

| Style | (Totally enclosed fan cooled) |

| Explosion proof | No |

| Frequency | 50Hz |

| Voltage / Amp draw | 230v / 1.7 |

| Voltage / Amp draw | 400v / 1.0 |

| Ship length | 91.44 cm (36") |

| Ship width | 60.96 cm (24") |

| Ship height | 66.04 cm (26") |

| Ship weight | 84.44 kg (186 Lb.) |

| Ship class | 70 |