Model 405-127

Omni-Lift Karrier Drum Racker to lift, move and place drum horizontally on rack. Single-phase 50Hz electric power lift, and hand crank drum tilt.

All about Model 405-127

- Model 405-127 has single-phase 50Hz AC motor for power lift, and Hand Crank drum tilt

- Switch raises drum

- Use Hand Crank to turn drum

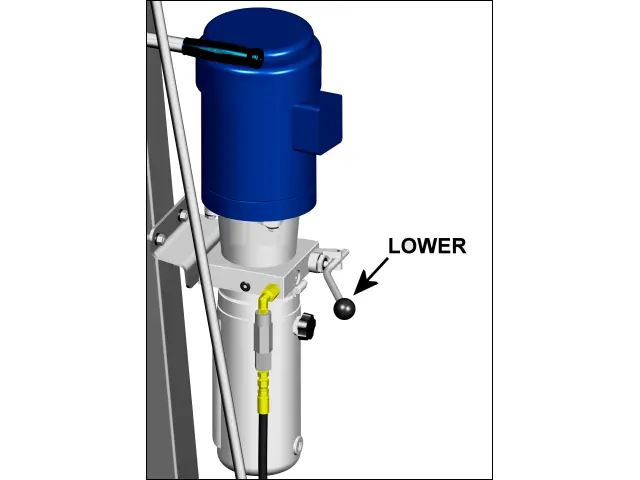

- Manual release valve lowers drum

- ONLY for use in country with 50Hz power supply

- Ships WITHOUT switch, cord and plug. Electrician to install according to local codes.

- Rack RIMMED 55-gallon (210L) STEEL drum in horizontal position

- To rack a RIMMED 55-Gallon (210L) PLASTIC drum, install Drum Pad Kit # 3313-P

- SAFETY CONSCIOUS Drum Racker to eliminate DANGEROUS bare fork drum handling

- Rack a RIMMED 55-gallon (210 Liter) steel or plastic drum up to 72" (183 cm) high

- Rack a drum horizontally with a drum faucet in place

|

1111i-p

option, factory installed auxiliary valve. Allows metering the lowering of the lift cylinder. Can be closed for postive hold. |

|

2386I-P

OPTION: Factory Installed Step Down Floor Lock on NEW 400 or 405 Series |

|

2843Xi-P

Fully enclosed crate for export of 400A-96 or 405 Series. Crate is heat treated and certified IPPC compliant. |

|

3313i-p

option, factory installed drum pads on 405 for handling a rimmed 55-gallon plastic drum. |

|

3900I-P

OPTION: Factory Installed MORStop Tilt-Brake on NEW manual tilt model. Auto holds drum tilt angle until you move it. |

|

6746-P

while supplies last |

|

FGO

OPTION: Factory Installed 1-Gallon of Food Grade Hydraulic Oil |

|

SCP-F

OPTION: Factory Installed switch, cord & F plug to 1PH/220V/50hz motor. F plug for Austria, Belgium, Czech Republic, France, Germany etc.. |

|

SCP-G

OPTION: Factory Installed switch, cord & G plug to 1PH/220V/50hz motor. G plug is for United Kingdom. |

OPTIONAL KIT, RECOMMENDED SPARE PARTS FOR MANUAL TILT 405 0617-____. Critical components to reduce risk of downtime and eliminate ship time.

No videos available.

Specifications

| Full capacity |

363.20 kg (800 Lb.) |

| Half capacity | 227.00 kg (500 Lb.)

Half-full capacity is an indication of the capacity for an unbalanced, bottom-heavy drum. A partially full drum with an unbalanced and shifting load is harder to tilt than a full drum. |

| Phase | 1 |

| Power | 0.7457 kw |

| Style | (Totally enclosed fan cooled) |

| Explosion proof | No |

| Frequency | 50Hz |

| Voltage / Amp draw | 220v / 6.2 |

| Ship length | 200.66 cm (79") |

| Ship width | 132.08 cm (52") |

| Ship height | 139.70 cm (55") |

| Ship weight | 204.30 kg (450 Lb.) |

| Ship class | 400 |