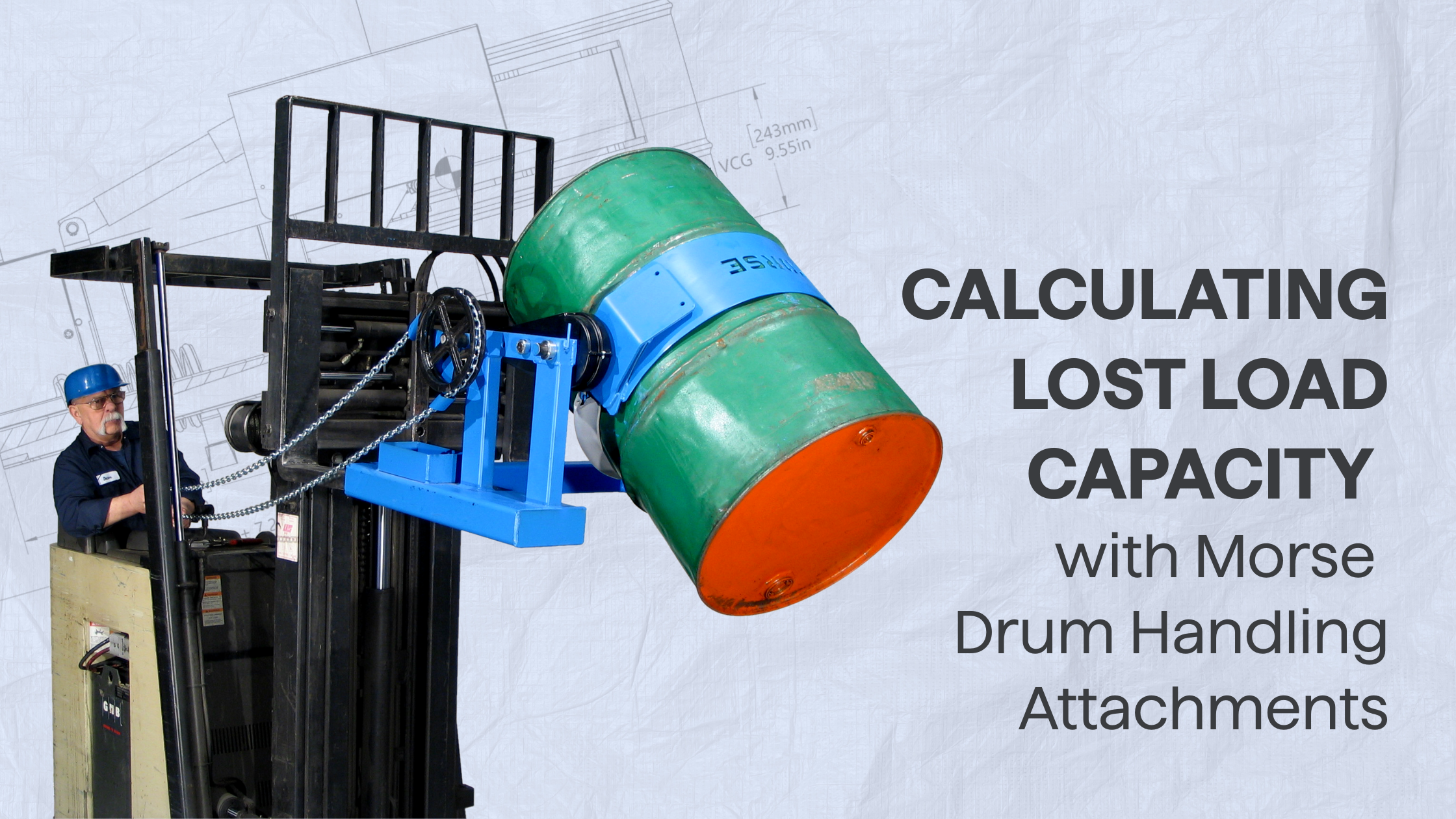

Calculating Lost Load Capacity with Morse Forklift Attachments

Forklift safety is paramount when using drum handling attachments, including calculating lost load capacity. While Morse Manufacturing provides the necessary information for calculating the effect of its drum handling attachments on forklift capacity, it is ultimately the responsibility of the forklift manufacturer or a qualified professional to determine the adjusted load capacity.

Why Load Capacity Calculation Matters

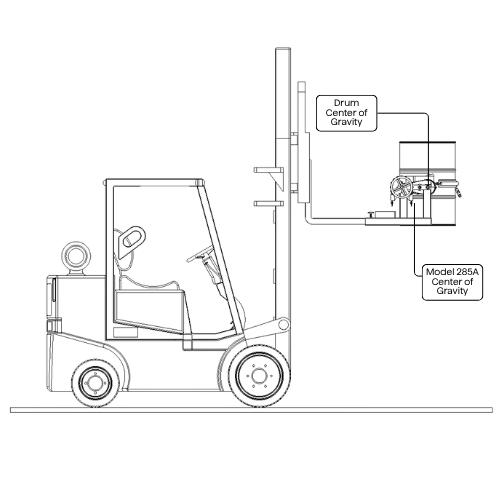

Adding a Morse drum handling attachment to a forklift shifts the center of gravity forward. This shift reduces the forklift’s overall capacity and increases the risk of tipping forward if not properly accounted for. Understanding and calculating this lost load capacity is crucial for:

- Ensuring forklift stability and safe operation

- Preventing potential damage to equipment

- Protecting forklift operators from hazardous conditions

- Limiting company liability in case of an accident

Steps to Determine Forklift Load Capacity with Attachments

- Alternative: Professional Engineer Approval – If the forklift manufacturer is unavailable or unwilling to provide guidance, OSHA allows for a registered professional engineer to perform a safety analysis and grant written approval for the attachment.

- Refer to the Operator’s Manual – Each Morse drum handling forklift attachment includes specifications for center of gravity and other key dimensions necessary for calculating lost load.

- Consult Your Forklift Manufacturer or Dealer – The manufacturer should provide guidance on how the attachment affects forklift capacity and update the nameplate accordingly.

OSHA Regulations for Forklift Attachments

OSHA has specific guidelines to ensure forklift modifications do not compromise safety:

- 1910.178(a)(4) – Any modification affecting capacity and safe operation must have the manufacturer’s written approval, and nameplates must be updated accordingly.

- 1910.178(a)(5) – Forklifts with aftermarket attachments must be marked to reflect the combined weight at maximum elevation.

- 1910.178(a)(6) – Nameplates and other markings must remain legible at all times.

OSHA’s Alternative Approval Process

If a forklift manufacturer is unresponsive or denies approval, OSHA’s letter of interpretation allows an employer to obtain written approval from a qualified registered professional engineer. This approval must include a detailed safety analysis addressing all concerns raised by the manufacturer.

For complete details, refer to OSHA’s letter of interpretation regarding regulation 1910.178(a)(4).

Conclusion

Properly calculating lost load capacity when using Morse drum handling attachments is essential for forklift safety and compliance. By following OSHA regulations and consulting the appropriate professionals, businesses can ensure safe and efficient drum handling operations. Always refer to the Operator’s Manual for specific attachment details and seek expert guidance when needed to maintain workplace safety

No responses yet