Drum Tumblers

Drum Tumblers

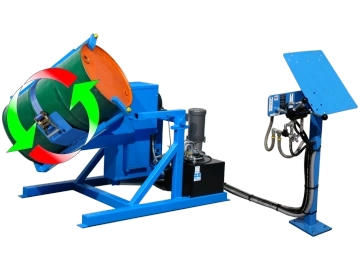

Thorough Mixing Inside a Closed Drum

Morse Drum Tumblers efficiently blend contents inside a sealed drum, eliminating contamination, reducing cleanup, and minimizing worker exposure. Designed for industrial applications, our drum tumblers ensure uniform mixing for a variety of materials.

Use Morse Drum Tumblers to:- Blend powders and solids evenly

- Ensure consistency in batch processing

- Mix drums of paint, oils, urethane resin, plastisol, glue, dyes, flavors, and more

- Homogenize chemical drums before use

- Grind and smooth parts with media for finishing applications

Achieve superior mixing results while keeping drum contents secure. Explore our industrial drum tumbling solutions today!

Let our dedicated team advise you about a solution that fits your needs

Request quotation

Unleash the power of productivity with our advanced power-propelled drum handlers.

Versatility is key in today's dynamic industries, and our power-propelled drum handling equipment rises to the challenge. Whether you're dealing with tight spaces, varied drum sizes, or demanding work environments, our equipment adapts to your needs. Customize your machine to fit your unique requirements, and experience the flexibility that sets our equipment apart.

Investing in our power-propelled drum handling equipment isn't just a purchase – it's a strategic decision to enhance your operational efficiency and streamline your processes. Join the ranks of satisfied customers who have witnessed a significant boost in productivity and an overall improvement in workplace safety.

About Morse