Drum Rollers

Drum Rollers

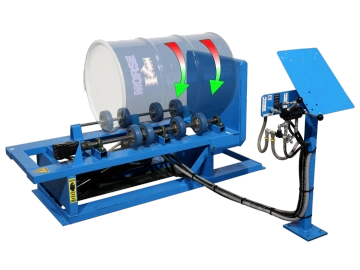

Morse Drum Rollers: Mix Closed Drums with Ease

Morse Drum Rollers provide a gentle yet effective way to mix the contents of a closed drum—no need to open or transfer materials. Designed to roll drums horizontally, our drum rollers ensure even blending for various applications.

As drum manufacturers have reduced sidewall thickness in recent years, it’s important to consider key factors for your drum mixing needs:

- Drum roller wheels may crack thin drum sidewalls

- Required drum rolling time for optimal mixing

- Weight of the drum and its impact on rotation

- Differences between mixing solid vs. liquid drum contents

For more vigorous mixing inside a drum, consider Morse Drum Tumblers, designed for thorough blending and enhanced performance.

Let our dedicated team advise you about a solution that fits your needs

Request quotation

Unleash the power of productivity with our advanced power-propelled drum handlers.

Versatility is key in today's dynamic industries, and our power-propelled drum handling equipment rises to the challenge. Whether you're dealing with tight spaces, varied drum sizes, or demanding work environments, our equipment adapts to your needs. Customize your machine to fit your unique requirements, and experience the flexibility that sets our equipment apart.

Investing in our power-propelled drum handling equipment isn't just a purchase – it's a strategic decision to enhance your operational efficiency and streamline your processes. Join the ranks of satisfied customers who have witnessed a significant boost in productivity and an overall improvement in workplace safety.

About Morse