Discover key features

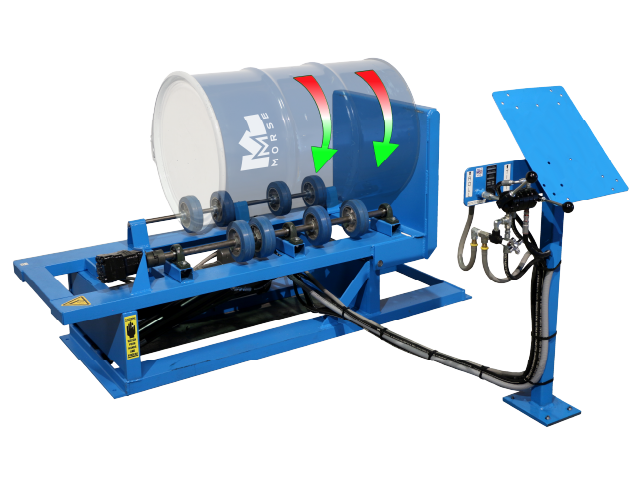

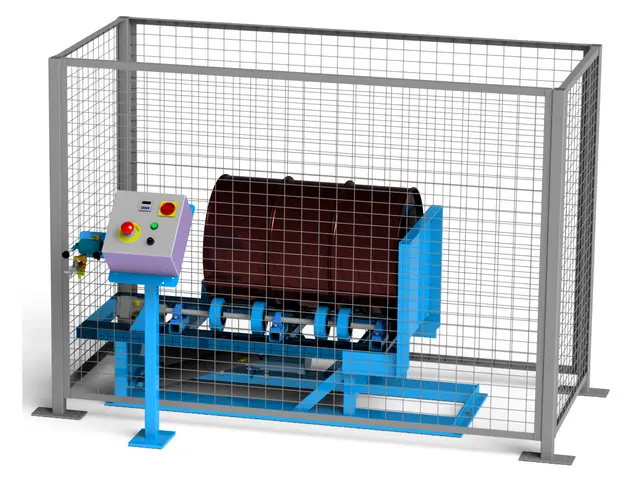

Remix settled ingredients with Drum Roller.

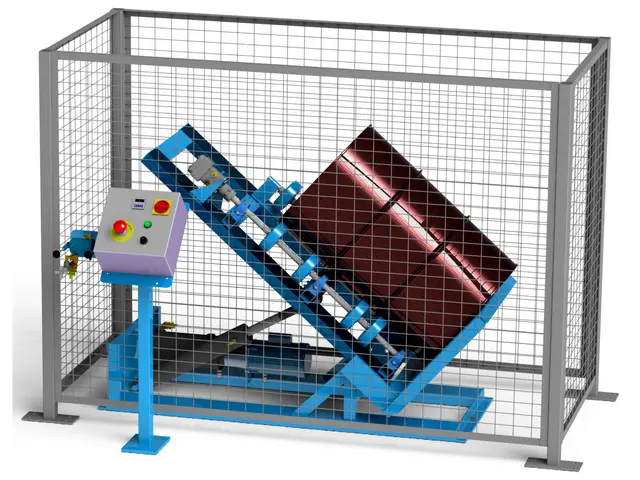

Hydraulic power to tilt upright drum over to horizontal rolling position.

Variable Drum Rolling Speed from 5 to 17 RPM (4 to 14 RPM for 50Hz models), based on a 22.5" diameter drum.

Designed to roll a steel drum.

Add options to roll a plastic drum or a 1-to-5 gallon cylindrical can.

Drum Handling SAFETY Features

- Load upright drum at floor-level with drum truck, etc.

- Mix right inside a closed drum. Nothing to insert into drum.

- Reduce spills, hazards and worker exposure

- Eliminate transfer, clean-up, and special vessels

Control Package and Guard Enclosure each sold separately.

Find the model that fits your needs

| Model | Motor style | Phase | Voltage / Amp Draw | Explosion proof | Drum RPM | Control Package | Guard Enclosure Kit |

|---|---|---|---|---|---|---|---|

| 456-1 | 60Hz | 1 | 115v / 12.8 208v / 7.0 230v / 6.4 |

|

5 to 17 RPM |

CP-456-1-115 CP-456-1-230 |

GEK-456-1 |

| 456-1-50 | 50Hz | 1 | 220v / 6.2 |  |

4 to 14 RPM |

CP-456-1-220-50 |

GEK-456-1 |

| 456-1-50-CE | 50Hz | 1 | 220v / 6.2 |  |

4 to 14 RPM | ||

| 456-3 | 60Hz | 3 | 208v / 3.1 230v / 3.0 460v / 1.5 |

|

5 to 17 RPM |

CP-456-3-230 CP-456-3-460 |

GEK-456-3 |

| 456-3-50 | 50Hz | 3 | 230v / 3.1 400v / 1.8 |

|

4 to 14 RPM |

CP-456-3-400-50 CP-456-3-230-50 |

GEK-456-3 |

| 456-3-50-CE | 50Hz | 3 | 400v / 1.8 |  |

4 to 14 RPM | ||

| 456-3-575 | 60Hz | 3 | 575v / 1.2 |  |

5 to 17 RPM |

CP-456-3-575 |

GEK-456-3 |

| 456-A | - |  |

5 to 17 RPM |

GEK-456-A |

|||

| 456-E1 | 60Hz | 1 | 115v / 12.4 208v / 6.7 230v / 6.2 |

|

5 to 17 RPM |

CP-456-E1-115 CP-456-E1-230 CP-456-E1-208 |

GEK-456-E1 |

| 456-E1-50 | 50Hz | 1 | 220v / 6.2 |  |

4 to 14 RPM |

CP-456-E1-220-50 |

GEK-456-E1 |

| 456-E3 | 60Hz | 3 | 208v / 3.1 230v / 3.0 460v / 1.5 |

|

5 to 17 RPM |

CP-456-E3-208 CP-456-E3-460 cp-456-e3-230 |

GEK-456-E3 |

| 456-E3-50 | 50Hz | 3 | 230v / 3.5 400v / 2.0 |

|

4 to 14 RPM |

CP-456-E3-400-50 CP-456-E3-230-50 |

GEK-456-E3 |

| 456-e3-575 | 60Hz | 3 | 575v / 1.2 |  |

5 to 17 RPM |

CP-456-E3-575 |

GEK-456-E3 |

456 Series Hydra-lift Drum Rollers

456 Series Hydra-lift Drum Rollers

Trusted Quality Manufacturing Since 1923

The Morse Mfg. plant and resources include skilled employees and certified welders, engineers, computer-controlled machining, and proprietary technology developed through 100 years of operations.

Bringing Safety & Ergonomics to Drum Handling

Let our dedicated team advise you about a solution that fits your needs

Request quotation

FIND MY MODEL

FIND MY MODEL