Discover key features

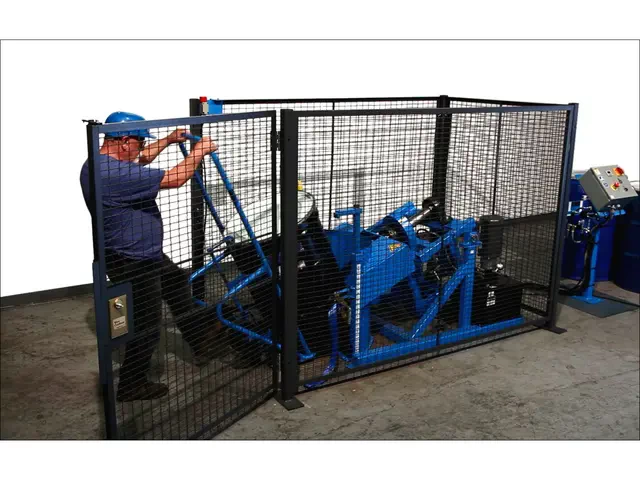

Drum Mixers blend contents of closed drum. Each Model includes Control Package and Safety Enclosure Kit.

Tumble a steel, plastic or fiber drum from 29" to 37" (74 to 94 cm) tall.

Tumble drum from 18" to 23.5" (46 to 60 cm) in diameter.

Variable Speed Drum Rotation.

Set drum rotation time from a few seconds to 16 hours.

Drum Handling SAFETY Features

- Easily load upright drum at floor level

- Mix right inside a closed drum

- Reduce spills, hazards and worker exposure

- Prevent messy cleanup and changeover

Find the model that fits your needs

| Product | Description |

|---|---|

| 311-1-115 | Controls Lift, Rotate for Set Time & Lower Drum. Includes Enclosure & interlock. |

| 311-1-220-50 | Controls Lift, Rotate for Set Time & Lower Drum. Includes Enclosure & interlock. |

| 311-1-230 | Controls Lift, Rotate for Set Time & Lower Drum. Includes Enclosure & interlock. |

| 311-3-230 | Controls Lift, Rotate for Set Time & Lower Drum. Includes Enclosure & interlock. |

| 311-3-230-50 | Controls Lift, Rotate for Set Time & Lower Drum. Includes Enclosure & interlock. |

| 311-3-400-50 | Tilt-To-Load Drum Tumbler, Automated Controls Lift, Rotate for Set Time & Lower Drum. 3-Phase 400V 50Hz Motor. Includes Enclosure & interlock. |

| 311-3-460 | Tilt-To-Load Drum Tumbler, Automated Controls Lift, Rotate for Set Time & Lower Drum. 3-Phase 460V 60Hz Motor. Includes Enclosure & interlock. |

| 311-3-575 | Tilt-To-Load Drum Tumbler, Automated Controls Lift, Rotate for Set Time & Lower Drum. 3-Phase 575V 60Hz Motor. Includes Enclosure & interlock. |

311 Series Automated Tilt-To-Load Drum Tumblers

311 Series Automated Tilt-To-Load Drum Tumblers

Trusted Quality Manufacturing Since 1923

The Morse Mfg. plant and resources include skilled employees and certified welders, engineers, computer-controlled machining, and proprietary technology developed through 100 years of operations.

Bringing Safety & Ergonomics to Drum Handling

Let our dedicated team advise you about a solution that fits your needs

Request quotation

FIND MY MODEL

FIND MY MODEL