Master Safe Drum Handling with the Morse 520-110 Drum Pourer

When handling heavy drums, efficiency and safe drum handling are paramount. The Morse 520-110 Drum Pourer is designed to provide controlled drum pouring while reducing the risk of injuries and spills. Whether you’re an operator looking for step-by-step guidance or a purchasing manager assessing drum handling solutions, this guide will walk you through the operation and safety precautions of the 520-110 model.

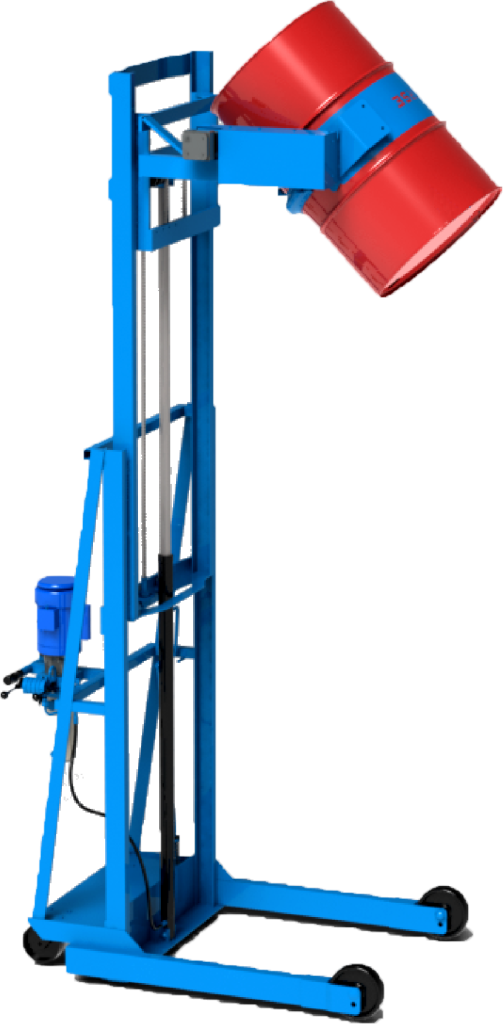

520-110 Drum Pourer Overview

The Morse 520-110 Drum Pourer is a versatile piece of equipment designed to lift, rotate, and pour 55-gallon (210-liter) drums with precision. Its ergonomic design allows a single operator to safely control drum handling with minimal effort. Key features include:

- Manual Hand Crank or Hand Wheel Tilt Control – Enables smooth drum rotation.

- Adjustable Drum Holder – Securely accommodates a variety of drum types.

- Locking Mechanism – Prevents unintentional movement during operation.

- Durable Steel Construction – Built for industrial use, ensuring longevity and reliability.

Step-by-Step Operating Instructions

1. Inspect the Equipment

Before use, always inspect the Drum Pourer for any signs of wear, damage, or loose components. Ensure all moving parts function correctly and that the unit is on a stable, level surface.

2. Secure the Drum

- Position the drum within the drum holder.

- Adjust the drum holder clamps to ensure a snug fit.

- Engage the locking mechanism to prevent any unintended movement.

3. Lift the Drum

- Use the hydraulic pump (if equipped) or manual lift mechanism to raise the drum to the desired height.

- Confirm that the drum is secure before proceeding to pour.

4. Rotate and Pour

- Use the hand crank or hand wheel to gradually tilt the drum forward.

- Control the pour speed to prevent splashing or spills.

- Pour the contents precisely into the receiving container or process area.

5. Return the Drum to the Upright Position

- Slowly rotate the drum back to its original position.

- Lower the drum safely to the ground before releasing the clamps.

Safe Drum Handling Precautions

To ensure safe operation of the Morse 520-110 Drum Pourer, always follow these safety guidelines:

- Wear Personal Protective Equipment (PPE) – Use gloves, safety glasses, and steel-toe boots to protect against spills and impact.

- Do Not Exceed the Weight Capacity – The unit is designed for specific drum sizes and weights. Overloading can result in equipment failure and accidents.

- Ensure a Clear Work Area – Keep the surrounding area free of obstructions to allow for smooth operation.

- Operate on a Level Surface – Using the Drum Pourer on uneven ground can lead to tipping hazards.

- Secure the Drum Properly – An improperly secured drum may shift unexpectedly, causing spills or injury.

- Follow Manufacturer’s Maintenance Guidelines – Regularly inspect and maintain the equipment to ensure optimal performance and safety.

Why Choose the Morse 520-110 Drum Pourer?

For companies handling liquid materials in 55-gallon drums, the Morse 520-110 Drum Pourer offers a reliable and efficient solution. Its user-friendly design minimizes strain on operators while enhancing workplace safety. Investing in quality drum handling equipment not only improves productivity but also reduces the risk of workplace injuries and spills.

For more details on the Morse 520-110 Drum Pourer, visit our product page or contact us for expert guidance on the best drum handling solutions for your operation.

No responses yet