Drum Tumblers vs. Drum Rollers – Choose the Right Mixing Solution

Compare Drum Tumblers and Drum Rollers for Mixing Sealed Drum Contents

Morse offers two reliable types of sealed drum mixing equipment: drum tumblers and drum rollers. Each solution provides a way to mix contents inside closed drums—reducing the risk of spills, exposure to hazardous materials, and product waste.

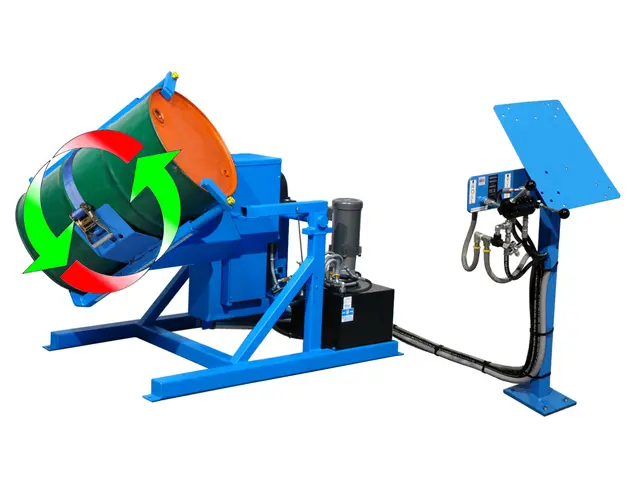

Drum tumblers rotate the entire drum end-over-end to create a vigorous, thorough blend of ingredients. This type of mixer is ideal when your application requires high-energy mixing or the materials inside the drum are particularly thick, stubborn, or prone to settling.

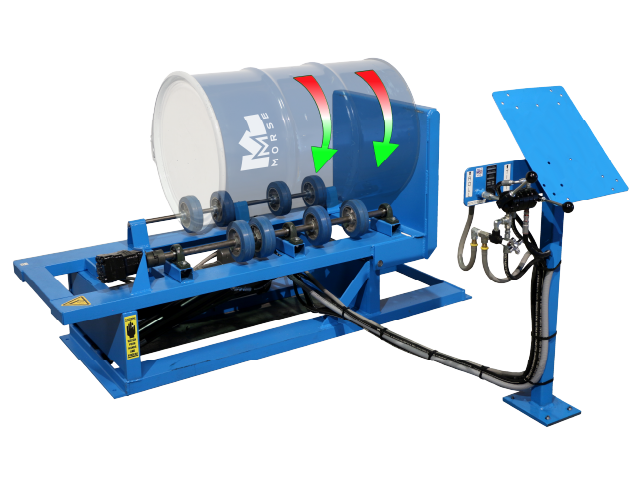

On the other hand, drum rollers rotate the drum on its side, using a gentler rolling action. This is a more energy-efficient option for blending materials that don’t require aggressive mixing. It’s also a great solution when space is limited or the drum must remain upright during processing.

Choosing between a tumbler and a roller depends on your drum size, material viscosity, mixing intensity needs, and facility requirements. Both options allow you to mix without opening the drum, helping you maintain a clean and safe work environment.

Not sure which mixing method is right for you? Contact our team of drum handling experts to discuss your application and get a recommendation tailored to your process.