- Drum Handling Products

- All Products

- Drum Rollers

- Drum Tumblers

- Mobile Drum Handlers

- Forklift Drum Handlers

- Below-Hook Drum Handlers

- Drum Rackers

- Drum Trucks

- Drum Palletizers

- Drum Dollies

- Drum Cradles

- Stainless Steel Drum Handlers

- Spark Resistant

- Accessories, Options & Kits

- 5-Gallon (20 Liter) Pail Handlers

- Custom Drum Handlers

- Resources

- About Morse

- FAQ

- CONTACT

The Drum Beat: Reloaded

Welcome to “The Drum Beat: Reloaded,” where we take Morse Manufacturing’s legacy of safety, innovation, and industry leadership to the next level. Stay tuned for the latest in drum handling solutions, product launches, safety tips, and company news—all reloaded for today’s fast-paced material handling world.

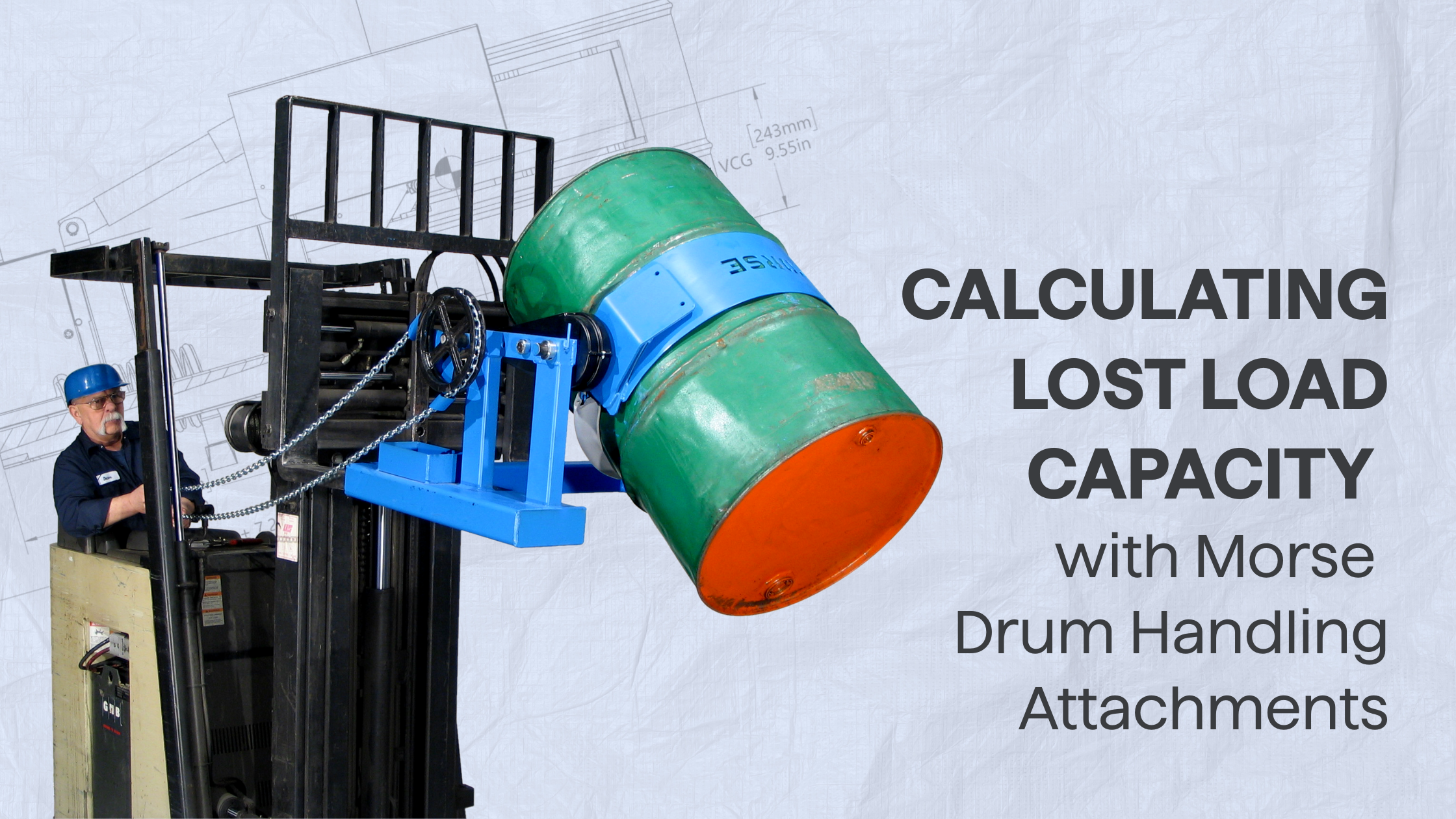

Calculating Lost Load Capacity with Morse Forklift Attachments

Calculating Lost Load Capacity with Morse Forklift Attachments Forklift safety is paramount when using drum[…]

June is National Safety Month: Prioritizing Safety in Every Drum Move

At Morse Manufacturing, safety isn’t just a feature—it’s a core value. As we recognize National[…]

Celebrating the First National Careers in Trades Week

Celebrating the First National Careers in Trades Week This year marks the first official National[…]

Morse Manufacturing Travels to Tampa for 2025 MHEDA Convention

Morse Manufacturing Travels to Tampa for 2025 MHEDA Convention Morse Manufacturing was proud to attend[…]

Morse Manufacturing Names Equipos de Elevación as Platinum Dealer

Morse Manufacturing Names Equipos de Elevación as Platinum Dealer EAST SYRACUSE, NY – Morse Manufacturing,[…]

How to Select the Right Below-Hook Drum Lifter for Your Drum

How to Select the Right Below-Hook Drum Lifter for Your Drum There is a below-hook[…]

ProMat & LogiMat 2025 Recap: Connecting, and Growing Together

ProMat & LogiMat 2025 Recap: Connecting, and Growing Together The Morse Manufacturing team recently returned[…]

Bare Fork Drum Handling Risks & Safer Alternatives

Bare Fork Drum Handling Risks & Safer Alternatives When it comes to moving heavy drums[…]

Morse Manufacturing Introduces the 82H-XR-125 Extended Reach Drum Handler

FOR IMMEDIATE RELEASE Morse Manufacturing Introduces the 82H-XR-125 Extended Reach Drum Handler Optimized for Cabinet[…]

Morse Earns MHEDA Most Valuable Supplier Award for 10th Year

Morse Manufacturing Earns MHEDA Most Valuable Supplier Award for 10th Consecutive Year Morse Manufacturing is[…]

Morse Manufacturing Unveils Bold Rebrand and Redesigned Website

Morse Manufacturing, the global leader in drum handling equipment, is proud to announce the launch[…]

Morse Manufacturing: Expanding Our Global Footprint

For over a century, Morse Manufacturing has been a trusted leader in drum handling solutions,[…]

Celebrating Ralph Phillips: 26 Years of Dedication, Expertise, and Laughter

Celebrating Ralph Phillips: 26 Years of Dedication, Expertise, and Laughter As we bid farewell to[…]

Safely Handling Plastic Drums with Morse Drum Handling Equipment

Safely Handling Plastic Drums with Morse Drum Handling Equipment Handling 55-gallon (210 liter) plastic drums[…]

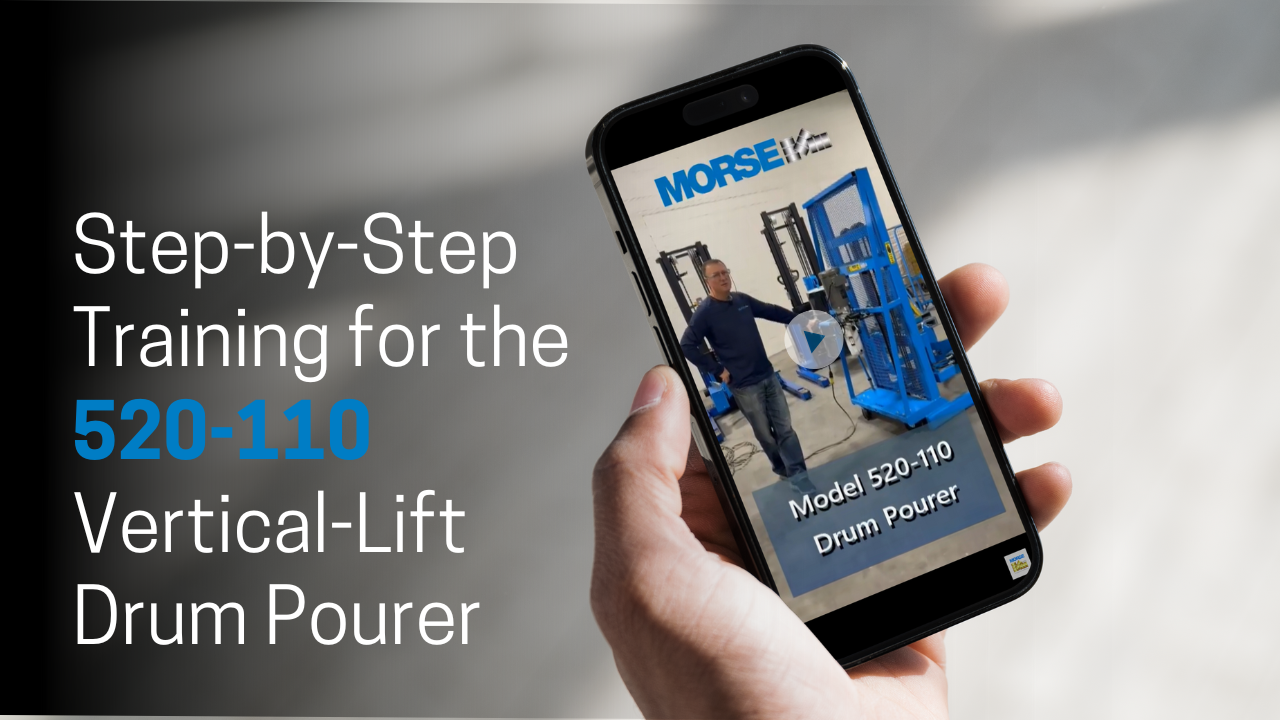

Master Safe Drum Handling with the Morse 520-110 Drum Pourer

Master Safe Drum Handling with the Morse 520-110 Drum Pourer When handling heavy drums, efficiency[…]

Ensuring Drum Handling Safety and Reliability: Maintaining Your Morse Equipment

Ensuring Drum Handling Safety and Reliability: Maintaining Your Morse Equipment When it comes to handling[…]

Drum Mixing Safety: Balancing Efficiency and Compliance

Drum Mixing Safety: Balancing Efficiency and Compliance This blog is based on the article “Drum[…]

Moving Drums On and Off Pallets: A Safety Guide

Moving Drums On and Off Pallets: A Safety Guide Handling heavy drums on and off[…]

Morse Manufacturing Named “Local Legend” at United Way of CNY State of Caring Awards

Morse Manufacturing Named “Local Legend” at United Way of CNY State of Caring Awards 🏆[…]

Preventing Back Strain & Repetitive Injuries in Drum Handling

The safety of your workers is a top priority, and investing in ergonomic equipment like[…]

Strategic Planning

Strategic Planning It feels like a new beginning as we move into our second century[…]

Morse Announces Platinum Dealer Program

Morse Announces Platinum Dealer Program The new Platinum Dealer Program not only aims to drive[…]

President’s Message

In case you’ve been living under a drum and haven’t heard, last year we celebrated[…]

Welcome Katie Stephens to the Morse Family

Welcome Katie Stephens to the Morse Manufacturing Family We’re excited to welcome Katie Stephens as[…]

Morse Manufacturing Celebrates its 100th Anniversary in Central New York

Morse Manufacturing Co., Inc. of 103 Kuhn Road Syracuse is celebrating its 100th Anniversary in[…]

Morse Celebrates 100 Years!

Morse is Celebrating 100 Years in BusinessDuring 2023 Morse is celebrating our 100th Anniversary with[…]

Morse showed off its New Factory in Syracuse, NY

Morse showed off its New Factory in Syracuse, NY About 150 people attended the ribbon[…]

Get in touch

Contact us Monday through Friday from 8:00 AM to 4:30PM

![]() (315) 437-8475

(315) 437-8475![]() inquiry@morsedrum.com

inquiry@morsedrum.com

© 2025 Morse Manufacturing. Created with ❤ using WordPress and Kubio