- Drum Handling Products

- All Products

- Drum Rollers

- Drum Tumblers

- Mobile Drum Handlers

- Forklift Drum Handlers

- Below-Hook Drum Handlers

- Drum Rackers

- Drum Trucks

- Drum Palletizers

- Drum Dollies

- Drum Cradles

- Stainless Steel Drum Handlers

- Spark Resistant

- Accessories, Options & Kits

- 5-Gallon (20 Liter) Pail Handlers

- Custom Drum Handlers

- Resources

- About Morse

- FAQ

- CONTACT

Posts in Drum Handling Safety Tips

Bare Fork Drum Handling Risks & Safer Alternatives

Bare Fork Drum Handling Risks & Safer Alternatives When it comes to moving heavy drums in an industrial setting, using[…]

Safely Handling Plastic Drums with Morse Drum Handling Equipment

Safely Handling Plastic Drums with Morse Drum Handling Equipment Handling 55-gallon (210 liter) plastic drums can be more challenging[…]

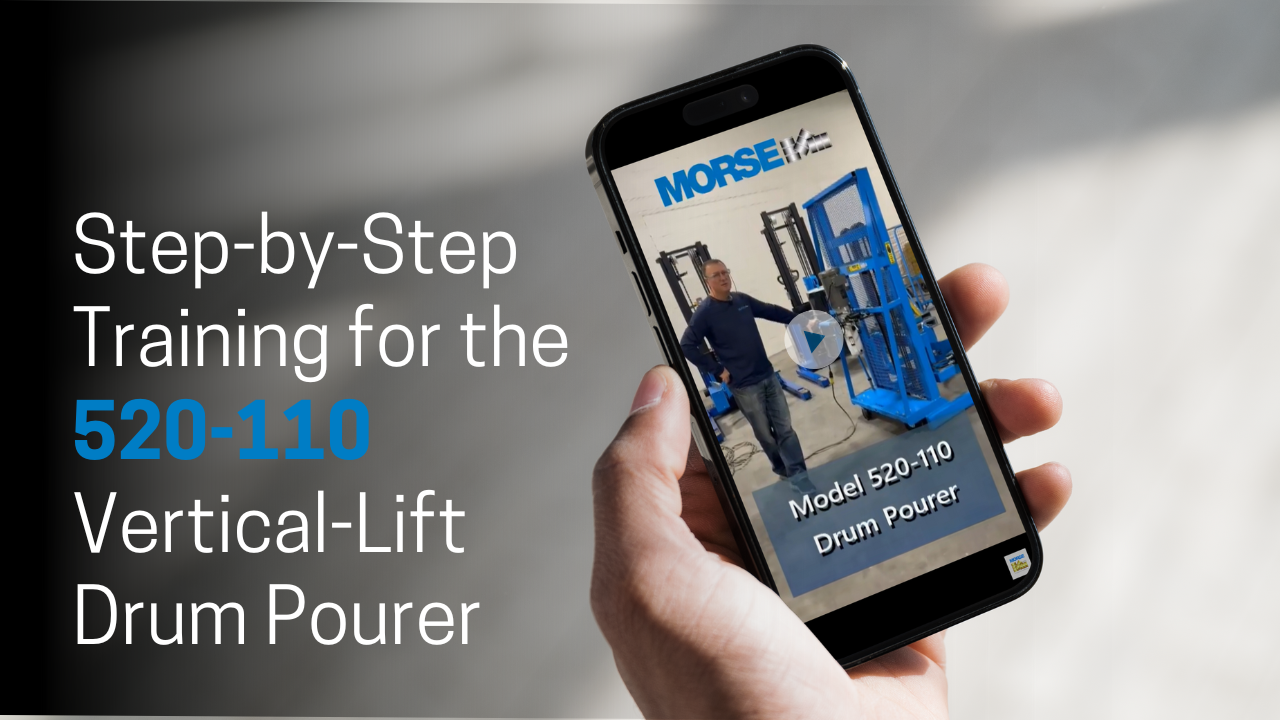

Master Safe Drum Handling with the Morse 520-110 Drum Pourer

Master Safe Drum Handling with the Morse 520-110 Drum Pourer When handling heavy drums, efficiency and safe drum handling[…]

Ensuring Drum Handling Safety and Reliability: Maintaining Your Morse Equipment

Ensuring Drum Handling Safety and Reliability: Maintaining Your Morse Equipment When it comes to handling heavy drums, drum handling[…]

Drum Mixing Safety: Balancing Efficiency and Compliance

Drum Mixing Safety: Balancing Efficiency and Compliance This blog is based on the article “Drum Mixing Safety” by Steve[…]

Moving Drums On and Off Pallets: A Safety Guide

Moving Drums On and Off Pallets: A Safety Guide Handling heavy drums on and off shipping pallets is a[…]

Preventing Back Strain & Repetitive Injuries in Drum Handling

The safety of your workers is a top priority, and investing in ergonomic equipment like Morse Drum Trucks and[…]

Explore Morse Drum Resources

BLOG CATEGORIES

SEARCH BY TAG

#SafetySaturday – Drum Handling Safety Company History & Legacy Drum Handling Guide Drum Handling Safety Drum Rotators Events Forklift Attachments MHEDA MORCINCH® Drum Handling Morse Community Platinum Dealer Program The Morse Message tradeshows tumblers united way

Get in touch

Contact us Monday through Friday from 8:00 AM to 4:30PM

![]() (315) 437-8475

(315) 437-8475![]() inquiry@morsedrum.com

inquiry@morsedrum.com

© 2025 Morse Manufacturing. Created with ❤ using WordPress and Kubio