Posts about Drum Handling Safety

Best practices, guidelines, and tips for safe drum handling in industrial settings. Learn how to reduce workplace injuries and improve efficiency.

Understanding what ergonomic drum handling really means helps teams reduce risk, improve consistency, and make smarter equipment decisions.

Manual handling of 55-gallon drums creates strain, increases spill potential, and leads to preventable injuries and downtime. Morse drum trucks are engineered to solve these challenges with safer, more ergonomic, and more efficient drum handling.

Learn the most important OSHA regulations for drum handling and how to document a compliant program. OSHA Compliance for Drum Handling Safety: What Facilities Must Know Key OSHA standards for […]

Unlocking Safer, Smarter Drum Handling with Morse Drum Palletizers When your team is handling 55-gallon drums, every lift, move, and set-down counts. That’s where Morse Drum Palletizers come in: engineered […]

The MORCinch: A Safer Way to Handle Drums Drums are heavy, awkward, and difficult to control without the right equipment. Relying on manual methods or makeshift solutions can put employees […]

In a competitive marketplace, it’s tempting to opt for the cheapest option. But when it comes to handling heavy, and sometimes hazardous, materials like 55-gallon drums, quality isn’t a luxury — it’s a necessity.

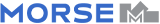

Calculating Lost Load Capacity with Morse Forklift Attachments Forklift safety is paramount when using drum handling attachments, including calculating lost load capacity. While Morse Manufacturing provides the necessary information for […]

Bare Fork Drum Handling Risks & Safer Alternatives When it comes to moving heavy drums in an industrial setting, using bare forklift forks is a risky choice. A drum slipping off […]

Safely Handling Plastic Drums with Morse Drum Handling Equipment Handling 55-gallon (210 liter) plastic drums can be more challenging than steel drums. Their smooth surfaces, lack of ribs, and slippery […]

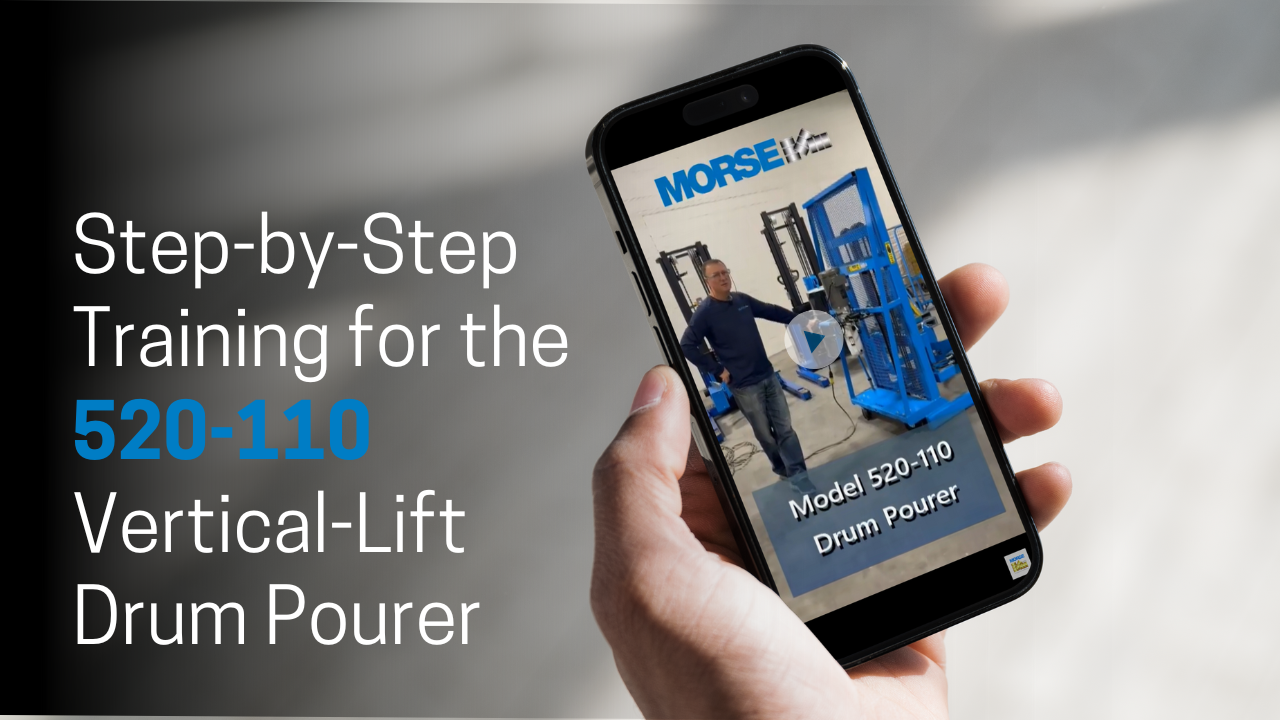

Master Safe Drum Handling with the Morse 520-110 Drum Pourer When handling heavy drums, efficiency and safe drum handling are paramount. The Morse 520-110 Drum Pourer is designed to provide […]