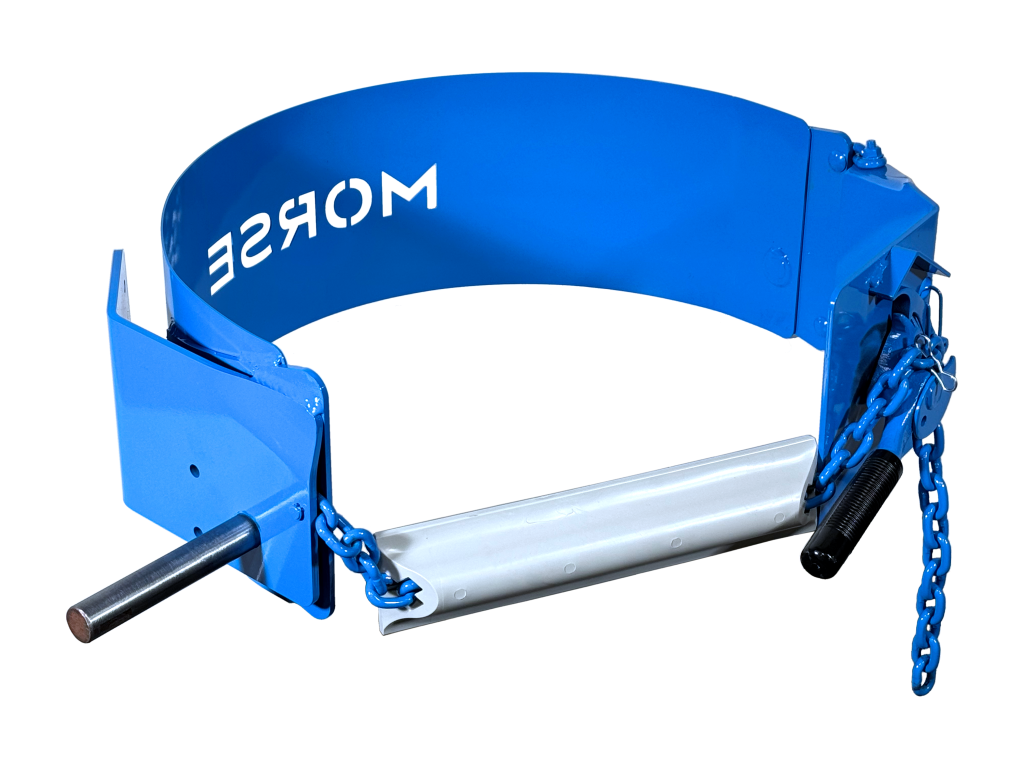

The MORCinch: A Safer Way to Handle Drums

Drums are heavy, awkward, and difficult to control without the right equipment. Relying on manual methods or makeshift solutions can put employees at serious risk of injury while slowing down productivity. That’s why Morse developed the MORCinch Drum Handling System—an engineered solution that secures drums safely and consistently, helping businesses protect their people and improve efficiency.

The Safety Challenge in Drum Handling

Manually lifting, balancing, or securing drums exposes workers to unnecessary hazards. Common risks include:

- Back and shoulder strain from repetitive lifting.

- Pinch points from improper gripping.

- Drums slipping or falling, causing spills or impact injuries.

These risks can be avoided with proper equipment designed specifically to do the job.

How the MORCinch Protects Workers

The MORCinch is engineered to reduce those risks by automatically adjusting to fit virtually any drum—without the need for manual changes or extra steps. Pair with one of the many diameter adapter options that Morse offers for a versatile system that will work with almost any drum you need to handle.

Key safety benefits include:

- Automatic Cinching: The system grips steel, fiber, and most plastic drums without relying on guesswork or adjustments.

- Secure Hold: Once engaged, the drum stays in place, preventing slips and drops.

- Reduced Strain: By eliminating the need for manual securing, employees avoid awkward lifting and pulling that lead to strains or sprains.

- Hands-Free Confidence: Operators can work with the assurance that drums are locked in securely before lifting, tilting, or pouring.

Built for Efficiency

Safety is the priority, but efficiency matters too. The MORCinch is compatible with Morse drum handlers and can be used across a wide range of applications, making it easy to integrate into existing operations. The rugged design ensures long service life, even under demanding industrial use.

Optional Upgrades for Extra Protection

Depending on the application, operators can further customize their MORCinch with options such as:

- Spark-Resistant Parts for hazardous environments.

- Stainless Steel Construction for corrosive or sanitary settings.

These options make the MORCinch adaptable to industries from chemical manufacturing to food processing.

Why It Matters

Every workplace injury avoided is a win—for both the employee and the business. The MORCinch not only reduces risks but also gives teams confidence that they’re working with equipment designed to put safety first. That peace of mind translates to higher productivity, fewer disruptions, and a stronger safety culture overall.

When it comes to drum handling, safety and efficiency don’t have to be a trade-off. The MORCinch Drum Handling System delivers both.

No responses yet