Discover key features

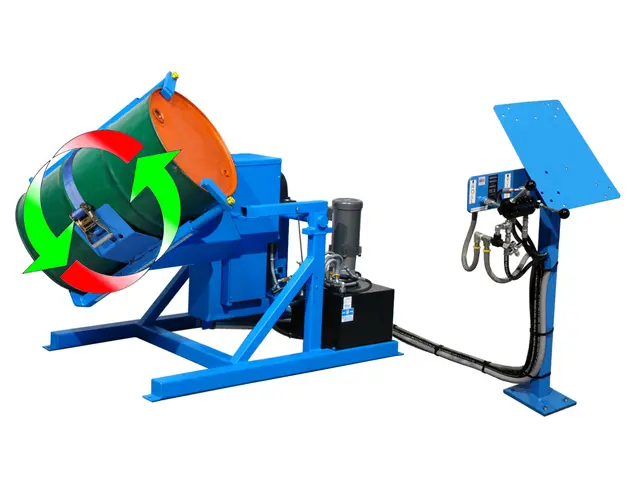

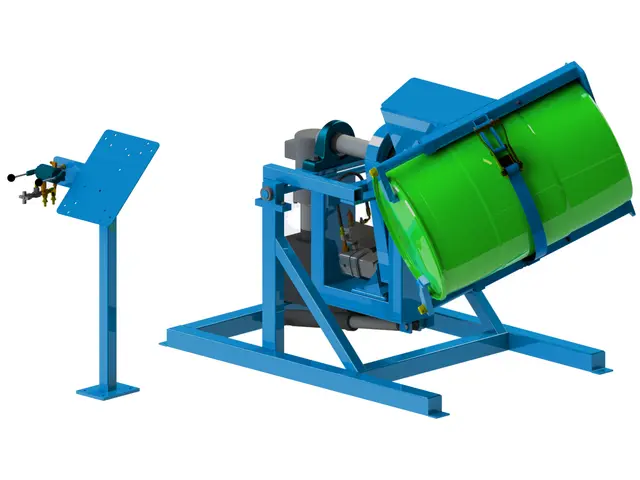

Mixers to blend drum contents.

Rotate plastic, steel or fiber 30 to 55 gallon (114 to 210 liter) drum.

Remix valuable settled or stratified ingredients.

Ensure homogeneous, uniform batches.

Smooth rough parts by tumbling with media.

IMPORTANT: OSHA requires enclosure with interlock.

Control Package and Guard Enclosure each sold separately.

Drum Handling SAFETY Features

- Easy to load upright drum at floor-level

- Mix right inside a closed drum

- Reduce spills, hazards and worker exposure

- Prevent messy cleanup and changeover

Find the model that fits your needs

| Model | Motor style | Phase | Voltage / Amp Draw | Explosion proof | Drum RPM | Control Package | Guard Enclosure Kit |

|---|---|---|---|---|---|---|---|

| 310-1 | 60Hz | 1 | 115v / 23.0 208v / 12.0 230v / 11.5 |

|

5 to 20 RPM |

CP-310-1-230 CP-310-1-115 |

GEK-310-1 |

| 310-1-50 | 50Hz | 1 | 220v / 9.7 |  |

4 to 16 RPM |

CP-310-1-220-50 |

GEK-310-1 |

| 310-1-50-ce | 50Hz | 1 | 220v / 9.7 |  |

4 to 16 RPM | ||

| 310-3 | 60Hz | 3 | 208v / 5.3 230v / 5.0 460v / 2.5 |

|

5 to 20 RPM |

CP-310-3-460 CP-310-3-230 |

GEK-310-3 |

| 310-3-50 | 50Hz | 3 | 230v / 5.0 400v / 2.9 |

|

4 to 16 RPM |

CP-310-3-400-50 CP-310-3-230-50 |

GEK-310-3 |

| 310-3-50-CE | 50Hz | 3 | 400v / 2.9 |  |

4 to 16 RPM | ||

| 310-3-575 | 60Hz | 3 | 575v / 2.0 |  |

5 to 20 RPM |

CP-310-3-575 |

GEK-310-3 |

| 310-a | - |  |

5 to 12 RPM |

GEK-310-A |

|||

| 310-E1 | 60Hz | 1 | 115v / 21.0 208v / 11.5 230v / 10.5 |

|

5 to 20 RPM |

CP-310-E1-230 CP-310-E1-208 CP-310-E1-115 |

GEK-310-E1 |

| 310-e1-50 | 50Hz | 1 | 220v / 9.8 |  |

4 to 16 RPM |

CP-310-E1-220-50 |

GEK-310-E1 |

| 310-E3 | 60Hz | 3 | 208v / 5.3 230v / 5.0 460v / 2.5 |

|

5 to 20 RPM |

CP-310-E3-460 CP-310-E3-230 CP-310-E3-208 |

GEK-310-E3 |

| 310-E3-50 | 50Hz | 3 | 230v / 5.5 400v / 3.2 |

|

4 to 16 RPM |

CP-310-E3-400-50 CP-310-E3-230-50 |

GEK-310-E3 |

310 Series Tilt-To-Load Drum Tumblers

310 Series Tilt-To-Load Drum Tumblers

Trusted Quality Manufacturing Since 1923

The Morse Mfg. plant and resources include skilled employees and certified welders, engineers, computer-controlled machining, and proprietary technology developed through 100 years of operations.

Bringing Safety & Ergonomics to Drum Handling

Let our dedicated team advise you about a solution that fits your needs

Request quotation

FIND MY MODEL

FIND MY MODEL